TIPS TO CONSIDER WHEN PURCHASING CLOSURES

When selecting Closures, pipeline operators should consider safety and performance factors. The TDW D2000 Closures with the ProSeries™ Advantage is the safest, most trusted closure on the market.

“Imitation is the sincerest form of flattery that mediocrity can pay to greatness.”

Don’t compromise safety and performance by settling for imitations. When it comes to closures, cutting corners isn’t an option. The safety of your crews, the integrity of your pipeline, and the efficiency of your operation all hinge on choosing the right product.

TDW’s D2000 ProSeries closures are backed by more than 100 years of engineering expertise, field experience, and continuous innovation.

When you invest in the D2000 ProSeries, you’re not just buying a closure—you’re choosing the best-in-class solution backed by a manufacturer who will be here for the lifetime of your pipeline.

the manufacturer

Proven track record – Does the manufacturer have decades of field-proven reliability, or are they new to the market? TDW closures have been rigorously tested and trusted by operators worldwide for generations.

Life cycle support – A closure is only as good as its support. Look at availability of parts, repair services, and consumables like O-rings and Pressure Warning Locks (PWLs). TDW ensures long-term support for every component.

See the D2000 Closure in action

SAFETY FIRST

The primary question: Does the design keep the operator out of the danger zone?

Operator positioning – With the D2000, operators can safely open the closure from outside the direct line of danger.

Pressure Warning Locks – Placement matters. PWLs located in the 12 o’clock position are less likely to collect debris than those on the door face. The D2000 design directs any retained pressure safely away from the operator.

Durability and spares – Unlike metal-to-metal seals that wear out quickly, TDW’s PWLs are supported with readily available O-rings and replacement parts, ensuring reliability and uptime.

Design AND FEATURES that matter

Simplicity of operation – Fewer moving parts mean fewer failure points and easier maintenance.

Ease of alignment – A single pivot point makes aligning the door with the collar straightforward and efficient.

Clamping surface design – Closures with parallel, non-wedging clamp-rings eliminate force transfer to holding components, reducing wear compared to tapered, wedging surfaces.

O-Ring LOCATION and performance

Sealing performance is critical, and O-ring placement makes a big difference.

Protected placement – O-rings positioned on the external outer edge of the collar are less likely to be damaged during pig loading or removal, and they’re better protected from debris.

Leak prevention – Properly compressed O-rings perform even at low pressure, reducing leak risks.

Material options – TDW offers multiple O-ring materials to suit varying operating conditions, giving operators flexibility and reliability.

TDW closures are there for the lifetime of your pipeline.

At Kerr Engineered Sales Company, we know closures inside and out. For over 73 years, we’ve been helping operators make the right decisions for pipeline safety and efficiency. As TDW’s representative since 1952, we stand firmly behind their products and their commitment to excellence.

TDW FIRSTS: ISOLATION TOOLS & FITTINGS IN ACTION

To help a customer isolate a section of a gas pipeline being upgraded and replaced, TDW employed three new applications of its technology, along with the first use of ZEVAC® cross-compression equipment.

To help a customer isolate a section of a gas pipeline being upgraded and replaced, TDW employed three new applications of its technology, along with the first use of ZEVAC® cross-compression equipment.

Isolating the Lines

TDW ProStopp® DS Isolation Tool

An East Coast gas company needed to replace a section of bare steel pipe as part of their infrastructure upgrade program. They were also installing a new gas regulator station on the same project. The 3,200 foot section of 16” and 10” pipeline, needed to be replaced without shutting off service to any customers.

TDW recommended the use of Spherical 3-WAY Tees at both locations. With Stops set thru the Spherical Tees, the line could be isolated while gas was still allowed to travel thru the system thru the new permanent bypass that was welded between the outlet of the two spherical tees.

To isolate the section of pipe, TDW technicians deployed a 16” STOPPLE® Train, a patented system designed to isolate sections of pipeline for maintenance or repairs while the line remains in service. The STOPPLE® Train Isolation Machine uses double block and bleed technology, featuring two Sealing Cups with a bleed port between to ensure secure isolation.

For isolating the 10-inch line, TDW deployed the 10-inch ProStopp® DS Isolation Tool, which also uses double block and bleed technology with two hydraulically activated plugging heads.

Redirecting Gas Instead of Venting

Once the isolations were set on the 16-inch and 10-inch lines, the trapped gas between the isolated sections needed to be removed so that the line could be cut and capped. Rather than venting the gas into the atmosphere the traditional method, TDW technicians utilized a ZEVAC® (Zero Emission Vacuum and Compressor) Quad to extract the gas from the isolated section and redirect it back into the existing 16-inch line.

Gas utilities implement cross-compression technology like ZEVAC for methane emissions reduction during live gas operations.

ZEVAC® extracts gas from the isolated section and redirects it into the 16-inch line.

After depressurizing the line, the team secured the area overnight. Upon returning, they verified that the isolation seals were intact, providing a 100% shut-off. With no gas remaining, the utility safely cut out the old section and welded end caps. This permanently rerouted gas thru the spherical tees and into the new section of pipe.

Conditioning the Line

TDW TOR 3-WAY Tee Bypass

Another TDW first on this project, TDW’s new 2-inch THREAD-O-RING™ (TOR) 3-WAY™ Tee was used to build a bypass line between the new and old pipelines. The utility did this two weeks before the isolation, when they were conditioning (pickling) the line. Once the STOPPLE and the ProStopp were set, the TOR 3-WAY Tee Bypass was employed as the suction and discharge point for the ZEVAC® machine during line conditioning.

When the bypass was no longer needed, the TOR 3-Way™ Tee was isolated using TDW’s new Temporary Isolation Plug (TIP). Used for the first time on site, the TIP allowed the utility to safely decommission the outlet on the TOR 3-Way Tee. After both lines were capped off, the TOR Plugs were set in the TOR fittings, enabling the utility to complete the fittings.

Results

This complex isolation project was completed on schedule, allowing the utility to safely install the sections of pipeline without shutting off service to any customers. The new TDW technologies utilized in this project included:

TDW 10-inch ProStopp® DS Isolation Tool

TDW 2-inch THREAD-O-RING™ (TOR) 3-WAY™ Tee

TDW Temporary Isolation Plug (TIP)

Additionally, TDW technicians effectively operated a ZEVAC® Quad cross-compression unit to redirect about 25,000 scf of gas back into the 16-inch line, effectively reducing the utility’s methane emissions. The collaboration between TDW’s isolation tools and ZEVAC® marked a successful first use of these combined technologies.

Our application specialists at Kerr Engineered Sales Company are available for demonstrations, team presentations, lunch and learns and site visits. We are here to help you optimize your gas utility operations and ensure the safety and efficiency of your equipment.

Kerr Engineered Sales Company has been representing leading pipeline repair and performance companies in Eastern US since the company was founded in 1952. Seventy three years later, KERR remains a family business delivering the highest quality service and expertise.

CLOSING TDW D2000 CLOSURES

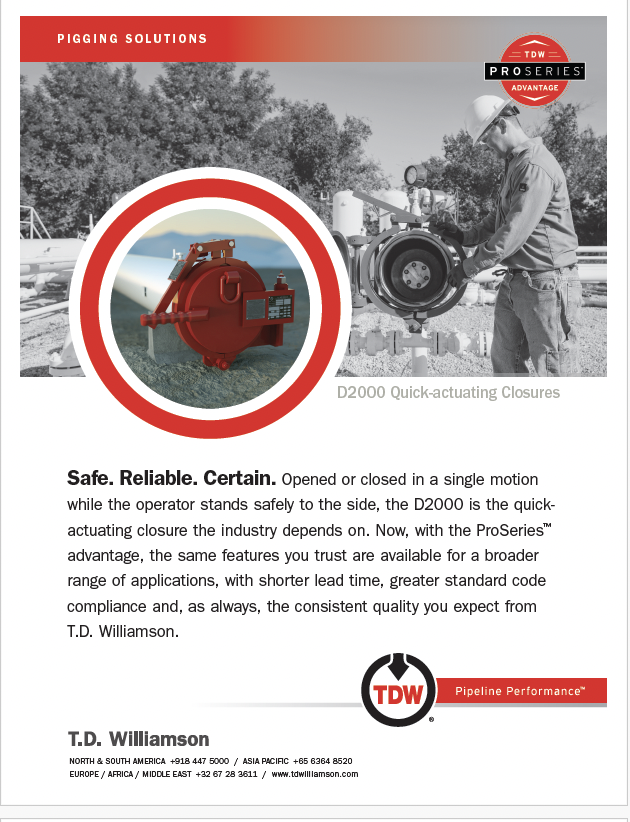

The D2000 quick-actuating closure combines operator safety with ease of operation. After depressurization, closing operations are performed in a fast, single motion. Here’s a quick guide to closing procedures.

TDW PIGGING INSIGHTS - Episode 6

A quick guide to closing and maintaining the D2000 Closure.

D2000 Quick-Actuating Closure

The D2000 quick-actuating closure combines operator safety with ease of operation. After depressurization, opening and closing operations are performed in a fast, single motion, with the operator standing safely to the side. The D2000 closure maximizes efficiency and reduces both, personal operator risk and company operational cost.

CLOSING PROCEDURES

Before closing, inspect, clean, and lubricate the O-Ring on the barrel collar, including the O Ring grooves and sealing surfaces

Push the door firmly shut with no gap between the door face and hub face.

Pull down on the clamp ring handle to close the door.

Install the pressure warning lock screw, make sure it is not cross threaded.

Hand tighten the pressure warning lock screw and then add about one eighth of a turn with a wrench. Do not over tighten.

MAINTENANCE TIPS TO BE DONE REGULARLY

Lubricate all the pivot point on top of the clamp ring assembly, front and back, as well as door hinge, top and bottom

Keep all the exterior surfaces painted to prevent rust

Other blogs you may be interested in:

If you have questions, please contact the Kerr Engineered Sales Company who are also available for team presentations, lunch and learns and customer visits.

SCHEDULE A TDW DEMONSTRATION

From Vermont to Virginia, the team at Kerr is on the road working with gas utilities and companies to ensure safe and efficient pipeline repair and maintenance. Gas utilities are investing in equipment such as the TDW POLYSTOPP® Quick Connect system.

From Vermont to Virginia, the team at Kerr is constantly on the road working with gas utilities and companies to ensure safe and efficient pipeline repair and maintenance.

Increasingly, gas utilities are investing in equipment such as the TDW POLYSTOPP® Quick Connect system. The POLYSTOPP® Quick Connect system makes it easy to safely perform hot tapping, plugging and branching on polyethylene (PE) pipelines. The lightweight design allows operators to isolate a polyethylene (PE) line twice as fast as other methods while preventing the damage associated with squeezing.

Recent product demonstrations have highlighted how to operate the equipment properly.

Daryl Smith, Cody Smith demonstrating TDW POLYSTOPP® Quick Connect to a New York City gas utility

For 72 years, Kerr has been supporting customers with all of their service and equipment needs. Our hands-on approach ensures that customers are fully equipped to operate their equipment safely and efficiently. We visit project sites and facilities, providing sessions that are tailored specifically for the equipment and applications the customer utilizes.

Components of a Demonstration

Equipment Setup and Installation: Step-by-step guidance on the proper installation of the POLYSTOPP® Quick Connect system.

Operational Best Practices: Detailed instructions on how to operate the equipment safely and effectively.

Maintenance Procedures: Tips and protocols for maintaining the equipment to ensure longevity and optimal performance.

Safety Protocols: Comprehensive safety guidelines to protect operators and bystanders.

Troubleshooting: Solutions to common issues that may arise during operation.

Ron Comer and Daryl Smith with the TDW POLYSTOPP® PE QUICK CONNECT at a New Jersey gas utility

A successful TDW POLYSTOPP® PE QUICK CONNECT demo at a gas utility in West Virginia

Daryl Smith assisting a customer

To schedule a training or a demonstration for your company, just reach out. We are here to help you optimize your gas utility operations and ensure the safety and efficiency of your equipment.

Kerr Engineered Sales Company has been representing leading pipeline repair and performance companies in Eastern US since the company was founded in 1952. Seventy two years later, the company remains a family business serving customers with the highest quality service and expertise.

Our application specialists at Kerr Engineered Sales Company are also available for demonstrations, team presentations, lunch and learns and customer visits.