BRUEST CATALYTIC HEATERS KEEP GAS FLOWING

As temperatures drop, the natural gas industry turns to Bruest for cost-efficient heating systems to prevent freeze-ups in critical metering and regulating equipment. Engineered for efficiency and safety, catalytic technology delivers consistent heat with minimal maintenance.

When temperatures drop, the natural gas industry turns to Bruest for cost-efficient heating systems to prevent freeze-ups in critical metering and regulating equipment. Engineered for efficiency and safety, catalytic technology delivers consistent heat with minimal maintenance.

Built in Independence, Kansas, Bruest engineers and manufactures reliable, efficient, flameless heat across the entire natural gas network in metering and regulating stations, analyzer shelters, compressor buildings, and pipeline manifolds.

The KERR team has decades of knowledge and hands-on expertise with catalytic heater operations, troubleshooting and start ups. Whether commissioning new units or maintaining systems that have been in service for decades, our Application Specialists work with customers to ensure every heater operates safely and performs at optimal levels.

Thomas Kerr starting a catalytic heater at a Compressor Building in Eastern PA. The flameless heat maintains temperatures above 50 degrees.

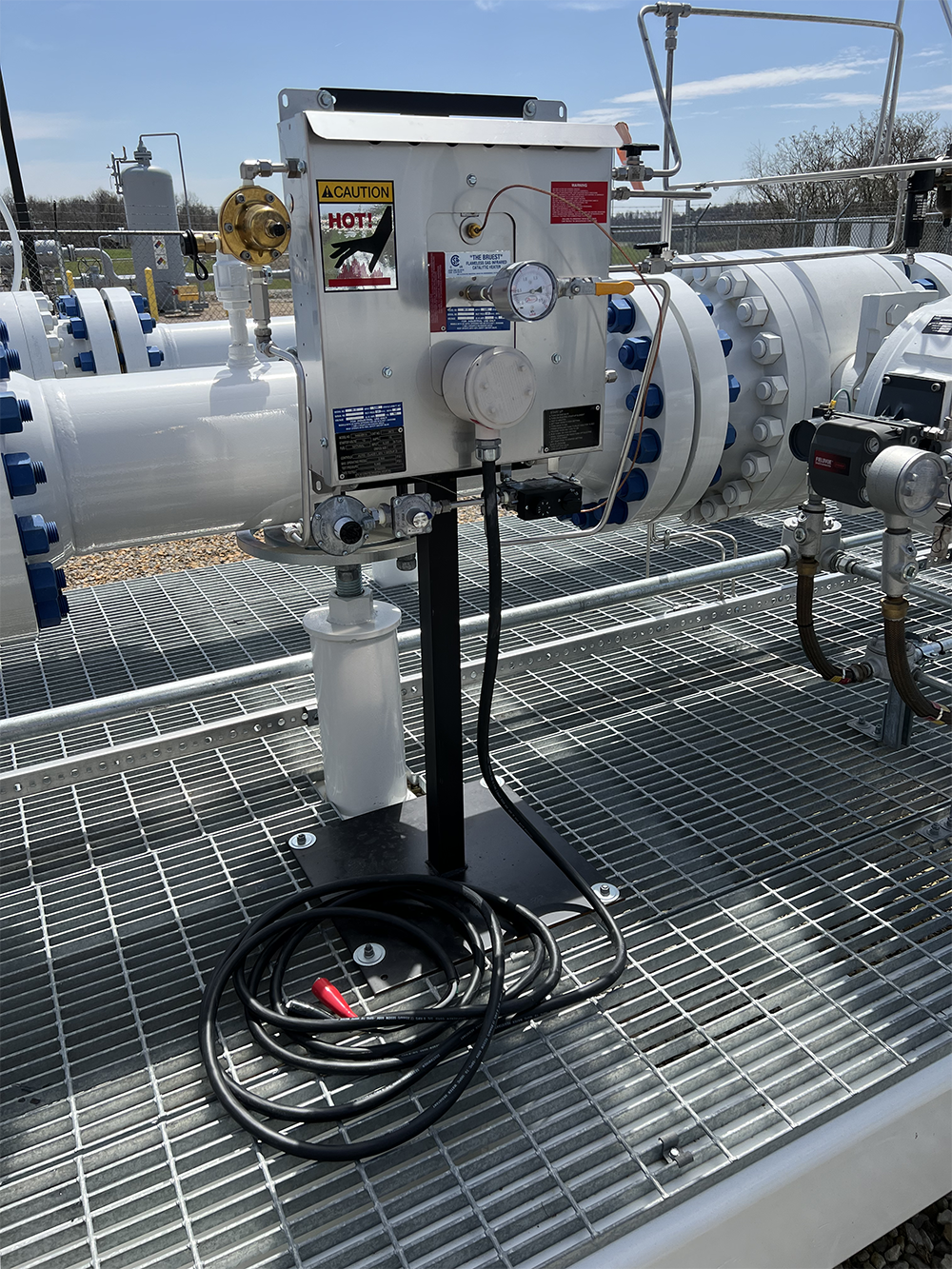

Freeze-FITER applied in front of an instrument preheats the gas

Thomas Kerr starting a Dual Coil Freez-FITER at a Compressor station

Bruest Catalytic Heaters are used wherever temperature control is critical, provide steady, flameless infrared heat to maintain proper operating temperatures in critical equipment.

Meter and regulator stations

Compressor buildings

Pipeline manifolds

Wellhead skids

Analyzer shelters and equipment enclosures

Catalytic Heater Fundamentals

Unlike conventional burners, catalytic heaters don’t rely on combustion. Instead, they use a catalytic reaction to release energy from natural gas or LPG at a much lower temperature—typically around 900°F (480°C) compared to the 1,200–1,400°F required for ignition. The result is safe, flameless infrared radiant heat—an exothermic chemical process that delivers steady warmth without sparks or smoke.

It’s not magic.. it’s an Exothermic chemical reaction.

DESIGNED FOR hazardous OR ENCLOSED ENVIRONMENTS

FREEZ-FITER with a Regulator

CSA Class I Div 1 or FM Class I Div 2

CSA and FM approvals for Class I, Division 1 and 2 locations

ATEX certification for European installations

Operates on natural gas or LPG

Catalytic Pads require little to no maintenance

No moving parts and minimal maintenance

Long service life with consistent, reliable output

HOTCAT LINE HEATERS

In HOTCAT natural gas line heaters, Bruest catalytic heater panels are the heat source. The catalytic heater panels convert the fuel gas to CO2, water vapor, and infrared heat with virtually no NOx. The process begins by preheating of the catalyst with electric power. Once the catalyst is preheated, fuel gas can be introduced to complete the startup. Manual or automated control systems are available for different application requirements.

David Kerr fine tuning a HOTCAT that heats fuel gas to power large, reciprocating compressors.

Cody Smith troubleshooting a HOTCAT at a regulator station in Virginia.

Daryl Smith diagnosed that the 11 yr old HOTCAT needed new heater pads.

resources

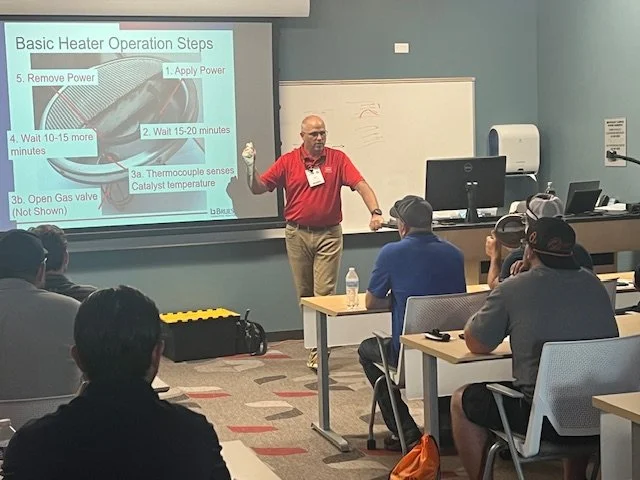

David Kerr teaching Bruest Heater Start Up and Operations

For Bruest Catalytic Heater support, training, maintenance or troubleshooting, connect with our Application Specialists.

MORE Applications for Catalytic Heaters

Since 1952, Kerr Engineered Sales Company has represented leading pipeline and performance equipment manufacturers across the Eastern U.S. Now in its fourth generation of family leadership, Kerr continues to serve the industry with the same commitment to quality, reliability, and personal service that has defined our company for more than 73 years.

TDW FIRSTS: ISOLATION TOOLS & FITTINGS IN ACTION

To help a customer isolate a section of a gas pipeline being upgraded and replaced, TDW employed three new applications of its technology, along with the first use of ZEVAC® cross-compression equipment.

To help a customer isolate a section of a gas pipeline being upgraded and replaced, TDW employed three new applications of its technology, along with the first use of ZEVAC® cross-compression equipment.

Isolating the Lines

TDW ProStopp® DS Isolation Tool

An East Coast gas company needed to replace a section of bare steel pipe as part of their infrastructure upgrade program. They were also installing a new gas regulator station on the same project. The 3,200 foot section of 16” and 10” pipeline, needed to be replaced without shutting off service to any customers.

TDW recommended the use of Spherical 3-WAY Tees at both locations. With Stops set thru the Spherical Tees, the line could be isolated while gas was still allowed to travel thru the system thru the new permanent bypass that was welded between the outlet of the two spherical tees.

To isolate the section of pipe, TDW technicians deployed a 16” STOPPLE® Train, a patented system designed to isolate sections of pipeline for maintenance or repairs while the line remains in service. The STOPPLE® Train Isolation Machine uses double block and bleed technology, featuring two Sealing Cups with a bleed port between to ensure secure isolation.

For isolating the 10-inch line, TDW deployed the 10-inch ProStopp® DS Isolation Tool, which also uses double block and bleed technology with two hydraulically activated plugging heads.

Redirecting Gas Instead of Venting

Once the isolations were set on the 16-inch and 10-inch lines, the trapped gas between the isolated sections needed to be removed so that the line could be cut and capped. Rather than venting the gas into the atmosphere the traditional method, TDW technicians utilized a ZEVAC® (Zero Emission Vacuum and Compressor) Quad to extract the gas from the isolated section and redirect it back into the existing 16-inch line.

Gas utilities implement cross-compression technology like ZEVAC for methane emissions reduction during live gas operations.

ZEVAC® extracts gas from the isolated section and redirects it into the 16-inch line.

After depressurizing the line, the team secured the area overnight. Upon returning, they verified that the isolation seals were intact, providing a 100% shut-off. With no gas remaining, the utility safely cut out the old section and welded end caps. This permanently rerouted gas thru the spherical tees and into the new section of pipe.

Conditioning the Line

TDW TOR 3-WAY Tee Bypass

Another TDW first on this project, TDW’s new 2-inch THREAD-O-RING™ (TOR) 3-WAY™ Tee was used to build a bypass line between the new and old pipelines. The utility did this two weeks before the isolation, when they were conditioning (pickling) the line. Once the STOPPLE and the ProStopp were set, the TOR 3-WAY Tee Bypass was employed as the suction and discharge point for the ZEVAC® machine during line conditioning.

When the bypass was no longer needed, the TOR 3-Way™ Tee was isolated using TDW’s new Temporary Isolation Plug (TIP). Used for the first time on site, the TIP allowed the utility to safely decommission the outlet on the TOR 3-Way Tee. After both lines were capped off, the TOR Plugs were set in the TOR fittings, enabling the utility to complete the fittings.

Results

This complex isolation project was completed on schedule, allowing the utility to safely install the sections of pipeline without shutting off service to any customers. The new TDW technologies utilized in this project included:

TDW 10-inch ProStopp® DS Isolation Tool

TDW 2-inch THREAD-O-RING™ (TOR) 3-WAY™ Tee

TDW Temporary Isolation Plug (TIP)

Additionally, TDW technicians effectively operated a ZEVAC® Quad cross-compression unit to redirect about 25,000 scf of gas back into the 16-inch line, effectively reducing the utility’s methane emissions. The collaboration between TDW’s isolation tools and ZEVAC® marked a successful first use of these combined technologies.

Our application specialists at Kerr Engineered Sales Company are available for demonstrations, team presentations, lunch and learns and site visits. We are here to help you optimize your gas utility operations and ensure the safety and efficiency of your equipment.

Kerr Engineered Sales Company has been representing leading pipeline repair and performance companies in Eastern US since the company was founded in 1952. Seventy three years later, KERR remains a family business delivering the highest quality service and expertise.

BRUEST CATALYTIC HEATERS IN ACTION

Bruest’s Catalytic Heaters are flameless, free of emissions, low maintenance and safe for hazardous locations. They offer multiple catalytic heating solutions for the natural gas industry. See the KERR team in action and get an overview of Bruest Catalytic Heater applications.

For 61 years, Kerr Engineered Sales has represented Bruest Catalytic Heaters, providing flameless, infrared catalytic heating solutions for the natural gas industry.

This article has a general overview of catalytic heater operations and applications.

The safest, most efficient alternative wherever flameless heat is required, Bruest Catalytic Heaters are found in heating applications along the gas network starting from the well head to the end user. Bruest leads the industry in engineering and manufacturing reliable, cost-efficient, green systems to prevent freeze-ups in critical metering and regulating equipment. Manufactured in Independence, Kansas, the catalytic heaters are used to heat meter buildings, platforms and pipelines.

David Kerr fine tuning a new HOTCAT that heats fuel gas to power large, reciprocating compressors.

KERR customers who have Bruest Catalytic Heaters count on our practical experience of how to start and operate the heaters. For fine tuning new heaters, or troubleshooting heaters that are decades old, our Application Specialists are on the ground to answer questions and provide support to ensure that the heaters are safe and working optimally.

BEnefits of bruest catalytic heaters

Thomas Kerr helping install and start up a series of Bruest flameless heaters at a Compressor Building. They replaced a boiler.

Catalytic Heater Fundamentals

Catalytic heaters produce flameless, infrared radiant heat. Bruest heaters cause natural gas to release its energy at a much lower temperature with a catalyst. The natural gas auto- ignition temperature is between 1200 - 1400 degrees Fahrenheit.

Bruest heaters operate at temperatures of around 900F-900F (426C to 483C.)

It’s not magic.. it’s an Exothermic chemical reaction.

bruest heaters are rated for hazardous locations

FREEZ-FITER with a Regulator

Bruest Catalytic Heaters are rated for operation by FM and CSA for operation in Class 1 Division 1 and 2 operation as well as ATEX for European applications. The catalytic heaters can be fueled with either Natural Gas or LPG.

CSA Class I Div 1 or FM Class I Div 2

Catalytic Pads require little to no maintenance

No moving parts

Catalytic heater at a Compressor Building in Eastern PA provides flameless heat to maintain temperatures above 50 degrees.

Thomas Kerr starting a Dual Coil Freez-FITER at a Compressor station

Freeze-FITER applied in front of an instrument preheats the gas

Cody Smith troubleshooting a HOTCAT at a regulator station in Virginia.

Daryl Smith diagnosed that the 11 yr old HOTCAT needed new heater pads.

MORE Applications for Catalytic Heaters

resources

For additional Bruest Catalytic Heater support, training, maintenance or troubleshooting, contact us to speak with KERR’s Application Specialists.

Kerr Engineered Sales Company has been representing leading pipeline repair and performance companies in Eastern US since the company was founded in 1952. Seventy two years later, the company is a third generation family run business serving customers with the highest quality service and support.

EGCR 2023 Marks 50 Year Kerr Legacy

Join the KERR team May 2-4, at Booth # 408 at the 2023 Eastern Gas Compression Roundtable (EGCR) in Pittsburgh, PA. David Kerr, 2023 Chairman of EGCR, is continuing a fifty year legacy of Kerr Engineered Sales and EGCR collaboration.

EGCR- May 2-4 David L. Lawrence Convention Center

Join David Kerr and Nigel Belshaw May 2-4 at Booth # 408 at the 2023 Eastern Gas Compression Roundtable (EGCR) in Pittsburgh. EGCR is a non-profit organization whose primary purpose is to provide the Natural Gas Industry with cost effective training programs focusing on engine and compressor maintenance. Countless operators, engineers, gas pipeline managers, industry leaders and insiders have gone through EGCR training.

One of the most popular tracks is the Entry Level Compressor Station Operator Training which focuses on the basics for those new to the industry including: yard piping, auxiliary systems, prime movers, compressor components and operating characteristics of reciprocating and centrifugal compressors.

ZEVAC Session: Compressor Unit and Station Maintenance without Blowdowns

ZEVAC MINI

Doug Sahm, PE, from ZEVAC, is leading a session Tuesday afternoon for Compressor Unit and Station Maintenance without Blowdowns. ZEVAC: Zero Emission Vacuum & Compressor is answering the call to eliminate blowdowns from compressors and compressor stations with new D3 technology that doesn't require any external power source (runs on station dP) and allows closed-loop design of the stations so that they are future-proofed and avoid any current or future methane penalty costs.

50 Year EGCR & KERR Legacy

David Kerr, Kerr Engineered Sales CEO is the Chairman of EGCR for 2023. David is continuing a fifty year legacy of Kerr Engineered Sales and EGCR collaboration. The first EGCR Roundtable was held in 1973 at West Virginia University. David’s Father, Arthur J. Kerr, Jr, President of Kerr Engineered Sales Co. was one of the early pioneers that led industry discussions addressing the need for training and support to address operating and maintenance for compressor systems.

Kerr Engineered Sales Company has been representing leading pipeline repair and performance companies in Eastern US since the company was founded in 1952. Seventy one years later, the company is still a family run business serving customers with the highest quality service and support.