BRUEST CATALYTIC HEATERS KEEP GAS FLOWING

When temperatures drop, the natural gas industry turns to Bruest for cost-efficient heating systems to prevent freeze-ups in critical metering and regulating equipment. Engineered for efficiency and safety, catalytic technology delivers consistent heat with minimal maintenance.

Built in Independence, Kansas, Bruest engineers and manufactures reliable, efficient, flameless heat across the entire natural gas network in metering and regulating stations, analyzer shelters, compressor buildings, and pipeline manifolds.

The KERR team has decades of knowledge and hands-on expertise with catalytic heater operations, troubleshooting and start ups. Whether commissioning new units or maintaining systems that have been in service for decades, our Application Specialists work with customers to ensure every heater operates safely and performs at optimal levels.

Thomas Kerr starting a catalytic heater at a Compressor Building in Eastern PA. The flameless heat maintains temperatures above 50 degrees.

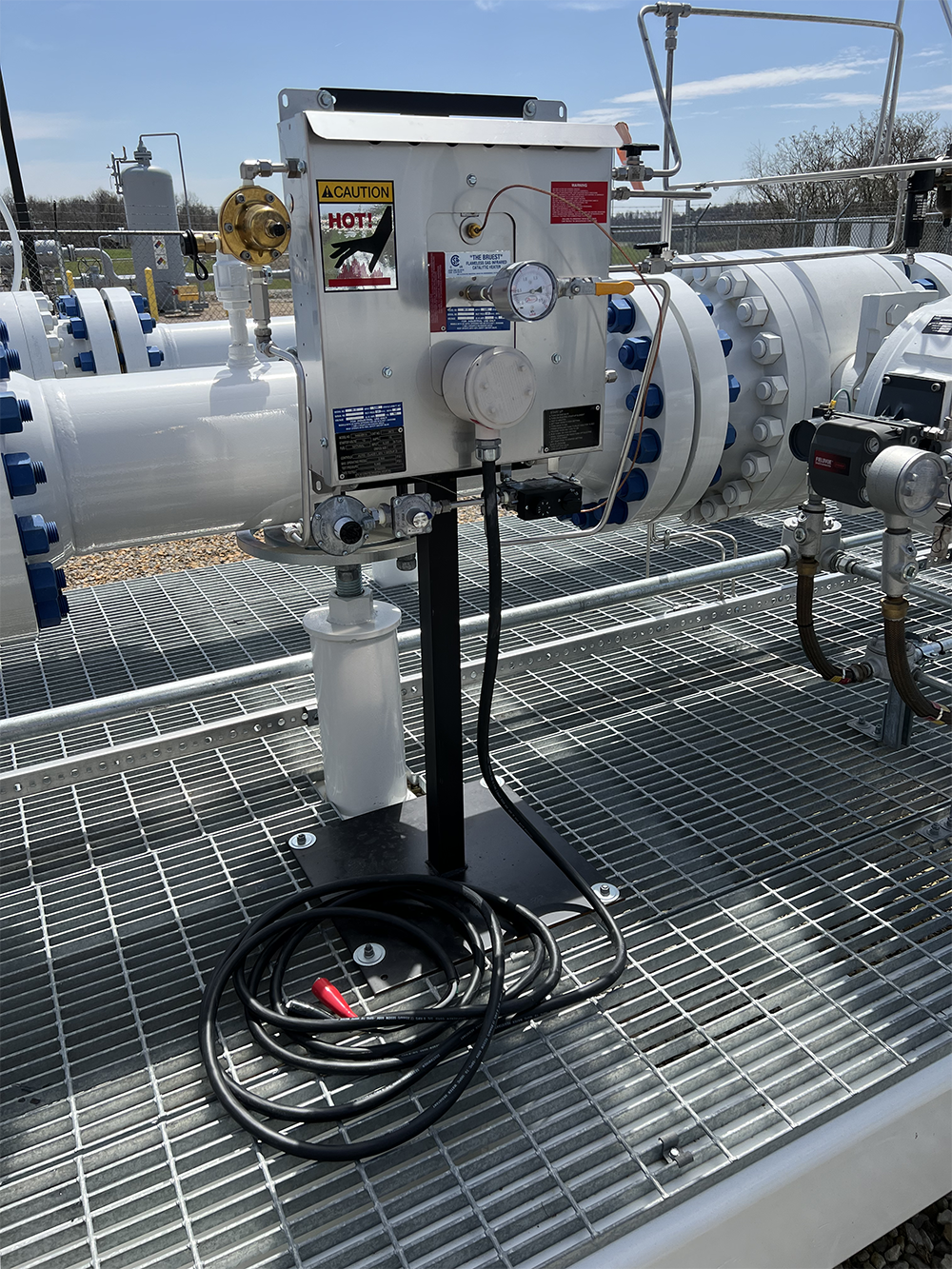

Freeze-FITER applied in front of an instrument preheats the gas

Thomas Kerr starting a Dual Coil Freez-FITER at a Compressor station

Bruest Catalytic Heaters are used wherever temperature control is critical, provide steady, flameless infrared heat to maintain proper operating temperatures in critical equipment.

Meter and regulator stations

Compressor buildings

Pipeline manifolds

Wellhead skids

Analyzer shelters and equipment enclosures

Catalytic Heater Fundamentals

Unlike conventional burners, catalytic heaters don’t rely on combustion. Instead, they use a catalytic reaction to release energy from natural gas or LPG at a much lower temperature—typically around 900°F (480°C) compared to the 1,200–1,400°F required for ignition. The result is safe, flameless infrared radiant heat—an exothermic chemical process that delivers steady warmth without sparks or smoke.

It’s not magic.. it’s an Exothermic chemical reaction.

DESIGNED FOR hazardous OR ENCLOSED ENVIRONMENTS

FREEZ-FITER with a Regulator

CSA Class I Div 1 or FM Class I Div 2

CSA and FM approvals for Class I, Division 1 and 2 locations

ATEX certification for European installations

Operates on natural gas or LPG

Catalytic Pads require little to no maintenance

No moving parts and minimal maintenance

Long service life with consistent, reliable output

HOTCAT LINE HEATERS

In HOTCAT natural gas line heaters, Bruest catalytic heater panels are the heat source. The catalytic heater panels convert the fuel gas to CO2, water vapor, and infrared heat with virtually no NOx. The process begins by preheating of the catalyst with electric power. Once the catalyst is preheated, fuel gas can be introduced to complete the startup. Manual or automated control systems are available for different application requirements.

David Kerr fine tuning a HOTCAT that heats fuel gas to power large, reciprocating compressors.

Cody Smith troubleshooting a HOTCAT at a regulator station in Virginia.

Daryl Smith diagnosed that the 11 yr old HOTCAT needed new heater pads.

resources

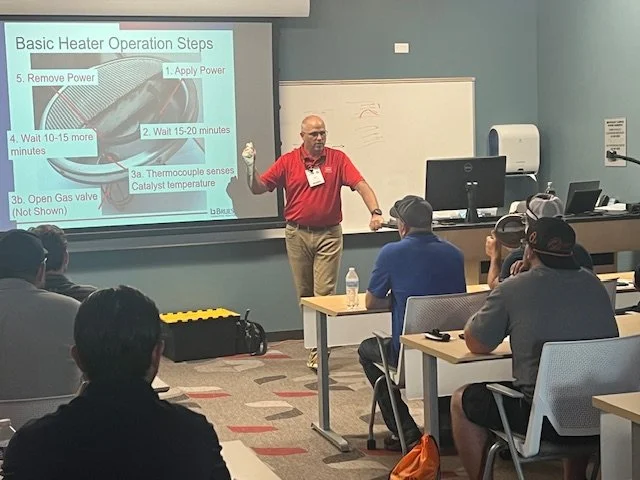

David Kerr teaching Bruest Heater Start Up and Operations

For Bruest Catalytic Heater support, training, maintenance or troubleshooting, connect with our Application Specialists.

MORE Applications for Catalytic Heaters

Since 1952, Kerr Engineered Sales Company has represented leading pipeline and performance equipment manufacturers across the Eastern U.S. Now in its fourth generation of family leadership, Kerr continues to serve the industry with the same commitment to quality, reliability, and personal service that has defined our company for more than 73 years.