BRUEST CATALYTIC HEATERS KEEP GAS FLOWING

As temperatures drop, the natural gas industry turns to Bruest for cost-efficient heating systems to prevent freeze-ups in critical metering and regulating equipment. Engineered for efficiency and safety, catalytic technology delivers consistent heat with minimal maintenance.

When temperatures drop, the natural gas industry turns to Bruest for cost-efficient heating systems to prevent freeze-ups in critical metering and regulating equipment. Engineered for efficiency and safety, catalytic technology delivers consistent heat with minimal maintenance.

Built in Independence, Kansas, Bruest engineers and manufactures reliable, efficient, flameless heat across the entire natural gas network in metering and regulating stations, analyzer shelters, compressor buildings, and pipeline manifolds.

The KERR team has decades of knowledge and hands-on expertise with catalytic heater operations, troubleshooting and start ups. Whether commissioning new units or maintaining systems that have been in service for decades, our Application Specialists work with customers to ensure every heater operates safely and performs at optimal levels.

Thomas Kerr starting a catalytic heater at a Compressor Building in Eastern PA. The flameless heat maintains temperatures above 50 degrees.

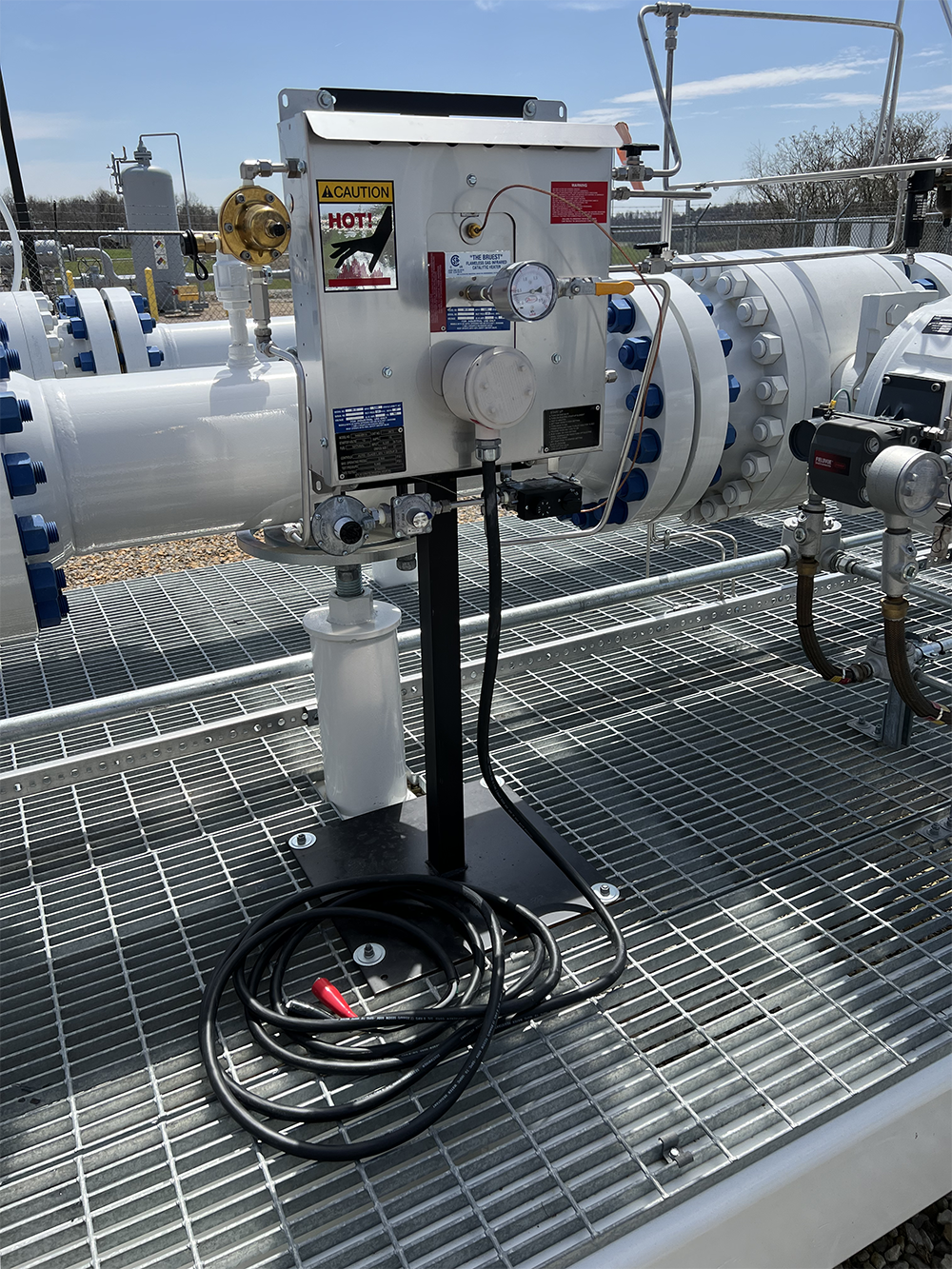

Freeze-FITER applied in front of an instrument preheats the gas

Thomas Kerr starting a Dual Coil Freez-FITER at a Compressor station

Bruest Catalytic Heaters are used wherever temperature control is critical, provide steady, flameless infrared heat to maintain proper operating temperatures in critical equipment.

Meter and regulator stations

Compressor buildings

Pipeline manifolds

Wellhead skids

Analyzer shelters and equipment enclosures

Catalytic Heater Fundamentals

Unlike conventional burners, catalytic heaters don’t rely on combustion. Instead, they use a catalytic reaction to release energy from natural gas or LPG at a much lower temperature—typically around 900°F (480°C) compared to the 1,200–1,400°F required for ignition. The result is safe, flameless infrared radiant heat—an exothermic chemical process that delivers steady warmth without sparks or smoke.

It’s not magic.. it’s an Exothermic chemical reaction.

DESIGNED FOR hazardous OR ENCLOSED ENVIRONMENTS

FREEZ-FITER with a Regulator

CSA Class I Div 1 or FM Class I Div 2

CSA and FM approvals for Class I, Division 1 and 2 locations

ATEX certification for European installations

Operates on natural gas or LPG

Catalytic Pads require little to no maintenance

No moving parts and minimal maintenance

Long service life with consistent, reliable output

HOTCAT LINE HEATERS

In HOTCAT natural gas line heaters, Bruest catalytic heater panels are the heat source. The catalytic heater panels convert the fuel gas to CO2, water vapor, and infrared heat with virtually no NOx. The process begins by preheating of the catalyst with electric power. Once the catalyst is preheated, fuel gas can be introduced to complete the startup. Manual or automated control systems are available for different application requirements.

David Kerr fine tuning a HOTCAT that heats fuel gas to power large, reciprocating compressors.

Cody Smith troubleshooting a HOTCAT at a regulator station in Virginia.

Daryl Smith diagnosed that the 11 yr old HOTCAT needed new heater pads.

resources

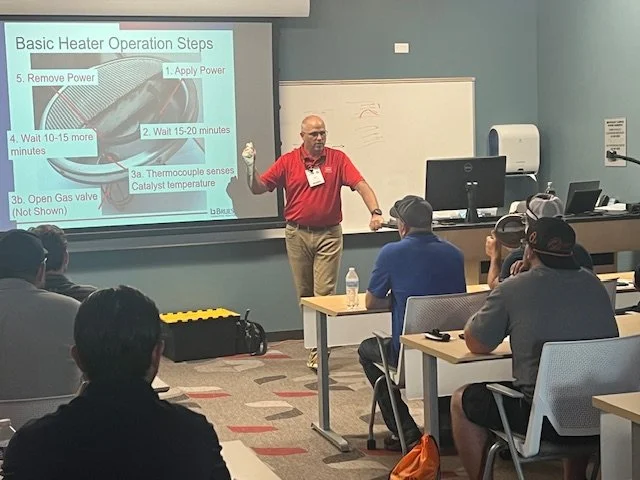

David Kerr teaching Bruest Heater Start Up and Operations

For Bruest Catalytic Heater support, training, maintenance or troubleshooting, connect with our Application Specialists.

MORE Applications for Catalytic Heaters

Since 1952, Kerr Engineered Sales Company has represented leading pipeline and performance equipment manufacturers across the Eastern U.S. Now in its fourth generation of family leadership, Kerr continues to serve the industry with the same commitment to quality, reliability, and personal service that has defined our company for more than 73 years.

BRUEST CATALYTIC HEATERS IN ACTION

Bruest’s Catalytic Heaters are flameless, free of emissions, low maintenance and safe for hazardous locations. They offer multiple catalytic heating solutions for the natural gas industry. See the KERR team in action and get an overview of Bruest Catalytic Heater applications.

For 61 years, Kerr Engineered Sales has represented Bruest Catalytic Heaters, providing flameless, infrared catalytic heating solutions for the natural gas industry.

This article has a general overview of catalytic heater operations and applications.

The safest, most efficient alternative wherever flameless heat is required, Bruest Catalytic Heaters are found in heating applications along the gas network starting from the well head to the end user. Bruest leads the industry in engineering and manufacturing reliable, cost-efficient, green systems to prevent freeze-ups in critical metering and regulating equipment. Manufactured in Independence, Kansas, the catalytic heaters are used to heat meter buildings, platforms and pipelines.

David Kerr fine tuning a new HOTCAT that heats fuel gas to power large, reciprocating compressors.

KERR customers who have Bruest Catalytic Heaters count on our practical experience of how to start and operate the heaters. For fine tuning new heaters, or troubleshooting heaters that are decades old, our Application Specialists are on the ground to answer questions and provide support to ensure that the heaters are safe and working optimally.

BEnefits of bruest catalytic heaters

Thomas Kerr helping install and start up a series of Bruest flameless heaters at a Compressor Building. They replaced a boiler.

Catalytic Heater Fundamentals

Catalytic heaters produce flameless, infrared radiant heat. Bruest heaters cause natural gas to release its energy at a much lower temperature with a catalyst. The natural gas auto- ignition temperature is between 1200 - 1400 degrees Fahrenheit.

Bruest heaters operate at temperatures of around 900F-900F (426C to 483C.)

It’s not magic.. it’s an Exothermic chemical reaction.

bruest heaters are rated for hazardous locations

FREEZ-FITER with a Regulator

Bruest Catalytic Heaters are rated for operation by FM and CSA for operation in Class 1 Division 1 and 2 operation as well as ATEX for European applications. The catalytic heaters can be fueled with either Natural Gas or LPG.

CSA Class I Div 1 or FM Class I Div 2

Catalytic Pads require little to no maintenance

No moving parts

Catalytic heater at a Compressor Building in Eastern PA provides flameless heat to maintain temperatures above 50 degrees.

Thomas Kerr starting a Dual Coil Freez-FITER at a Compressor station

Freeze-FITER applied in front of an instrument preheats the gas

Cody Smith troubleshooting a HOTCAT at a regulator station in Virginia.

Daryl Smith diagnosed that the 11 yr old HOTCAT needed new heater pads.

MORE Applications for Catalytic Heaters

resources

For additional Bruest Catalytic Heater support, training, maintenance or troubleshooting, contact us to speak with KERR’s Application Specialists.

Kerr Engineered Sales Company has been representing leading pipeline repair and performance companies in Eastern US since the company was founded in 1952. Seventy two years later, the company is a third generation family run business serving customers with the highest quality service and support.

USE CASE FOR TDW 3-WAY TEE

A gas operator in PA who was building a compressor station needed to tie in a new branch line to an existing 10 inch natural gas gathering line that was running at 950 psi. The customer did not want to leave a buried flanged connection underground that was in the ground.

TDW 3-WAY TEE IDEAL SOLUTION FOR TIE IN

10”x 10” 3-WAY TEE on the main line with sandwich valve

A gas operator in PA who was building a compressor station needed to tie in a new branch line to an existing 10 inch natural gas gathering line that was running at 950 psi. The customer did not want to have a buried flanged connection underground and were proposing to weld on a standard fitting, add a long pup piece to the fitting, attach a ball valve to the pup piece, and then bolt on the new 10 inch line to the valve above ground level. There were challenges in terms of the stack up. One issue was the length of travel that a tapping machine would have to navigate, the line needed a pup piece to be welded on, and the 10 inch main line was pigged and needed to remain so.

As an alternative, the Kerr and TDW specialists recommended to the operator to use a 10 inch by 10 inch Full Encirclement 3-WAY Tee with LOCK-O-RING ® Flange and LOCK-O-RING® Completion plug with flow through pig guide bars. This solution had multiple advantages. It eliminated the need for a long pup piece. There would not be an issue with the length of travel the tapping machine would have to navigate, and the line would remain piggable. The gas operator agreed.

LOR plug with pig flow through guide bars being attached to the tapping machine.

For this project, TDW technicians performed the welding of the 3-Way Tee fitting and the 10 inch branch line to the side outlet of the fitting. The Technicians operated the 10 inch Hot Tap and set the completion plug with the pig guide bars.

The result for the gas operator was a new branch line tied in with the 10 inch main line able to be pigged. This was the end result the customer required.

A successful result with a new branch line and 10” main that can be pigged.

To learn more about TDW Pigs or find Resource guides, see TDW Pig Resource page.

If you have questions, please contact the Kerr Engineered Sales Company who are also available for team for presentations, lunch and learns and customer visits.