BRIDGING THE SKILLS GAP FOR YOUNG PIPELINE PROFESSIONALS

Kerr, along with T.D. Williamson and ZEVAC are playing a vital role helping companies such as National Grid invest in the next generation of young pipeline professionals. Read about the movement.

Kerr Engineered Sales, with T.D. Williamson and ZEVAC are playing a vital role helping companies such as National Grid transfer essential industry knowledge to the next generation of pipeline professionals.

The natural gas industry is facing a generational shift. Veteran engineers and technicians who spent their entire career building and maintaining the backbone of the oil & gas industry are retiring. In the pipeline and distribution sector, over a quarter of employees in key roles are “at or near retirement age.” (McKinsey) As they exit, decades of institutional knowledge and field expertise is at risk of disappearing.

At the same time, utility work has grown in complexity. Roles are increasingly specialized. Conventional industry conferences cater to those who already understand advanced technologies and applications. The younger and new-to-the-industry professionals are eager to accelerate their careers, but they haven’t been exposed to advanced applications and equipment. The result is a widening experience gap.

Ian Kornfeld, Regional Engineering Manager at National Grid is working to close that gap for young and new professionals to learn and ask questions from technical experts. In collaboration with Young Pipeline Professionals USA (YPP USA) and National Grid, he is championing events and initiatives to increase engagement and fuel career growth for the next generation.

Building Your Pipeline Pathway: A New Approach to Career Development

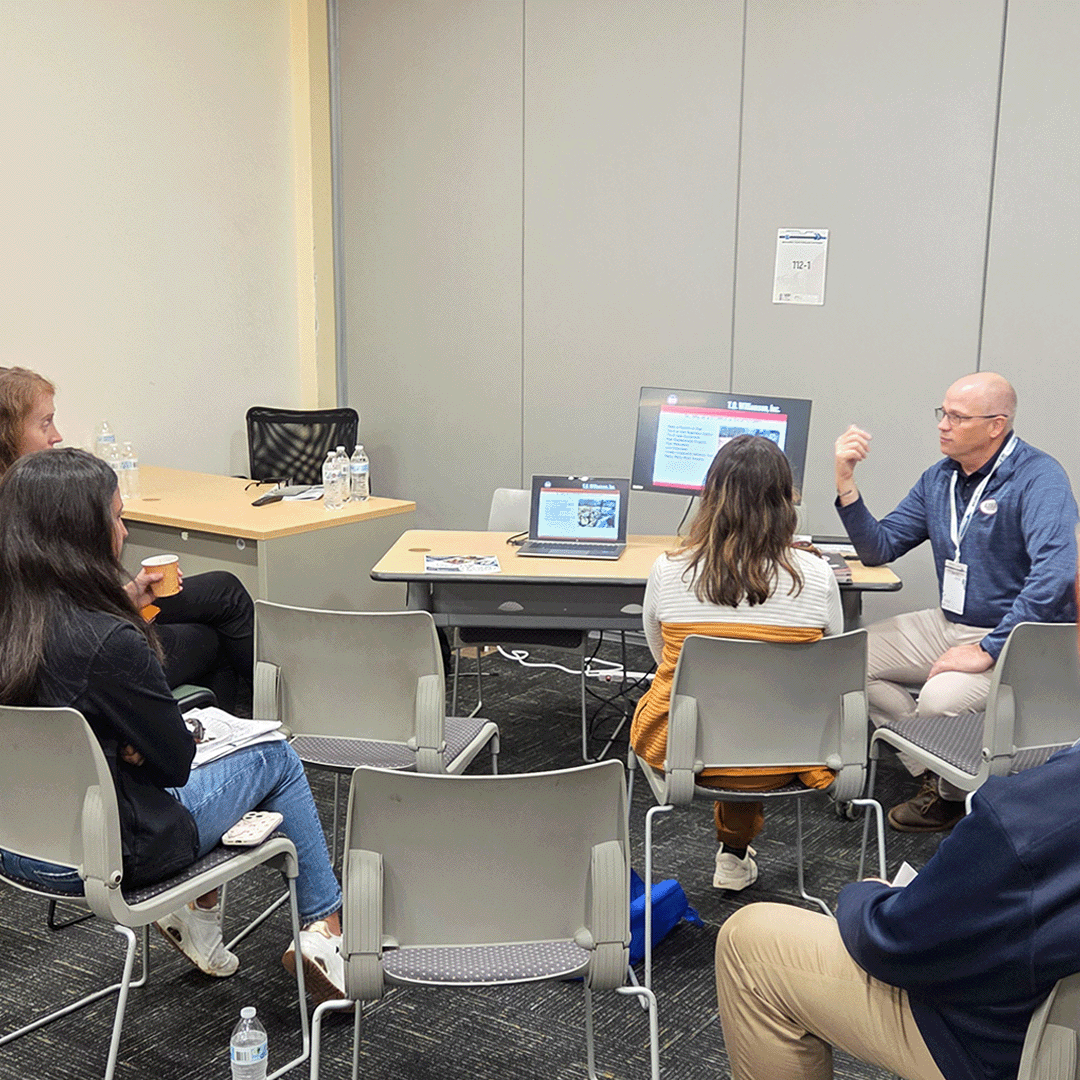

More than 115 individuals from the Northeast met at the National Grid Training Center in Melville, NY, for the 2025 Building Your Pipeline Pathway. The day had two objectives:

Provide high level overviews of key equipment, processes, and applications used in day-to-day operations.

Create an inclusive environment of continuous learning and curiosity.

Participants from all aspects of the industry rotated through 30-minute technical sessions led by subject matter experts. The topics and vendors were selected based on feedback from last year’s event.

Topics included:

Hot Tapping & Isolation- David Kerr & Ron Comer, Kerr Engineered Sales

State-of-the-art equipment and tools essential for safe repairs and maintenance of pressurized pipelines while the system stays in operation.

“We brought in experts who teach—not sell. David Kerr isn’t just an expert. He taught Hot Tapping and Isolation fundamentals - what it is, how the equipment operates, and why it matters.”

In-Line Inspection (ILI)- Jason Matocha, T.D. Williamson

ILI utilizes smart sensors to detect corrosion and generate precise data for repair plans, safety and compliance. Jason showed how ILI tools work, the kinds of anomalies seen and how the data can help pipeline operators make educated decisions to keep pipelines operating safely.

Cross-Compression- Michael Stephens, ZEVAC

The equipment and technology used to avoid gas venting and reduce methane emissions. Cross compression is a hot topic for National Grid and the wider industry.

Ian led a session about career development and hurdles he overcame. He urged folks to consider multiple paths within the industry, from integrity to construction to environmental compliance, to find their area of interest.

A scavenger hunt by National Grid’s Learning & Development team kept engagement high. Afterwards, a happy hour solidified new connections.

Feedback was very positive. The sessions generated interest to learn more; there was steady dialogue and lots of questions.

Championing a Movement

When Ian joined the utility in 2016, he struggled to find avenues to learn the basics.

“There wasn’t anyone officially championing young professionals,” he said. “I followed the experienced guys around and pried them for information. I asked a lot of questions. It took a lot of persistence. As I was exposed to all types of projects—transmission, distribution, gate stations, heaters and major repairs, it started making sense.”

Searching for ways to broaden his network, he discovered Young Pipeline Professionals USA, a Houston based organization with National membership. Through YPP USA, he met industry peers and got involved in leadership. He learned about broader aspects of the industry, including legal, customer relations, construction and finance.

Convinced that there was value in a mentorship and training ecosystem for the Northeast, Ian pitched to National Grid leadership. Without investing in foundational knowledge development, he explained, the company risked losing employees to more enticing career paths. Leadership agreed. Ian set forth to champion the effort, understanding the massive undertaking and time commitment, but with an end goal in mind.

Advice for Advancement: Ask Questions and Get Involved

The industry’s most experienced gas engineers and technicians started in the trenches and worked in all facets of the gas industry. Many spent their career at one utility and became experts. By identifying issues and problems, innovative solutions emerged. A lot of pride came with that mastery.

Ian wonders if the veterans aren’t making time to give their experience away to the next generation because no one is asking them questions.

He knows from his own journey, the path to a successful career in the gas industry is fueled by asking questions, seeking experience and getting involved.

Curiosity and Community

Ian wants to reverse the trend of employees sitting in silence when they don’t know the questions to ask or don’t want to look inexperienced. Instead of waiting for the knowledge to come to them, they must go out and get it.

“Instead of focusing on how to get ahead," he urged. “Be curious. Seek out the experienced folks. If you don’t ask questions until you truly understand, you’ll never advance.”

While the pipeline industry is large in scope, the community of vendors, contractors and operators is small and tight knit, Ian explained. Getting involved leads to meeting the right people and learning. When you run into them again, you build a community that starts to feel like a family.

What’s Next: Growing the Movement

Plans to strengthen the profession and build bridges for collaboration include:

Establishing a formal Northeast YPP USA chapter

Developing structured succession planning

Creating ongoing mentorship programs

Providing regular technical deep dives for early-career employees

As the next generation builds foundational knowledge, Ian is confident these initiatives will spark a steady flow of new ideas and innovations. Gas operations are more efficient due to those who challenged the old way of doing things. Instead of the mindset “we’ve always done it this way,” he encourages the question, “Is there a better way?”

About Ian Kornfeld - Regional Engineering Manager, National Grid, Melville, NY

Ian has been in the gas pipeline industry for 10 years. He manages a team responsible for the engineering, design and technical oversight of large-scale capital projects, with a yearly capital budget of over $150 million. Ian was part of the team that designed, built and completed a 10 mile multiyear, 30 inch diameter high pressure gas main throughout Brooklyn, New York. He is a licensed Mechanical Professional Engineer in New York, Massachusetts, Rhode Island and Maine. Other certifications include Project Management Professional, Certified Construction Manager, API 1169 as well as Institute for Asset Management.

About Kerr Engineered Sales Company. Since 1952, KERR has represented leading pipeline and performance equipment manufacturers across the Eastern U.S. Now in its fourth generation of family leadership, the team continues to serve the industry with the same commitment to quality, reliability, and personal service that has defined our company for more than 74 years.

BRUEST CATALYTIC HEATERS KEEP GAS FLOWING

As temperatures drop, the natural gas industry turns to Bruest for cost-efficient heating systems to prevent freeze-ups in critical metering and regulating equipment. Engineered for efficiency and safety, catalytic technology delivers consistent heat with minimal maintenance.

When temperatures drop, the natural gas industry turns to Bruest for cost-efficient heating systems to prevent freeze-ups in critical metering and regulating equipment. Engineered for efficiency and safety, catalytic technology delivers consistent heat with minimal maintenance.

Built in Independence, Kansas, Bruest engineers and manufactures reliable, efficient, flameless heat across the entire natural gas network in metering and regulating stations, analyzer shelters, compressor buildings, and pipeline manifolds.

The KERR team has decades of knowledge and hands-on expertise with catalytic heater operations, troubleshooting and start ups. Whether commissioning new units or maintaining systems that have been in service for decades, our Application Specialists work with customers to ensure every heater operates safely and performs at optimal levels.

Thomas Kerr starting a catalytic heater at a Compressor Building in Eastern PA. The flameless heat maintains temperatures above 50 degrees.

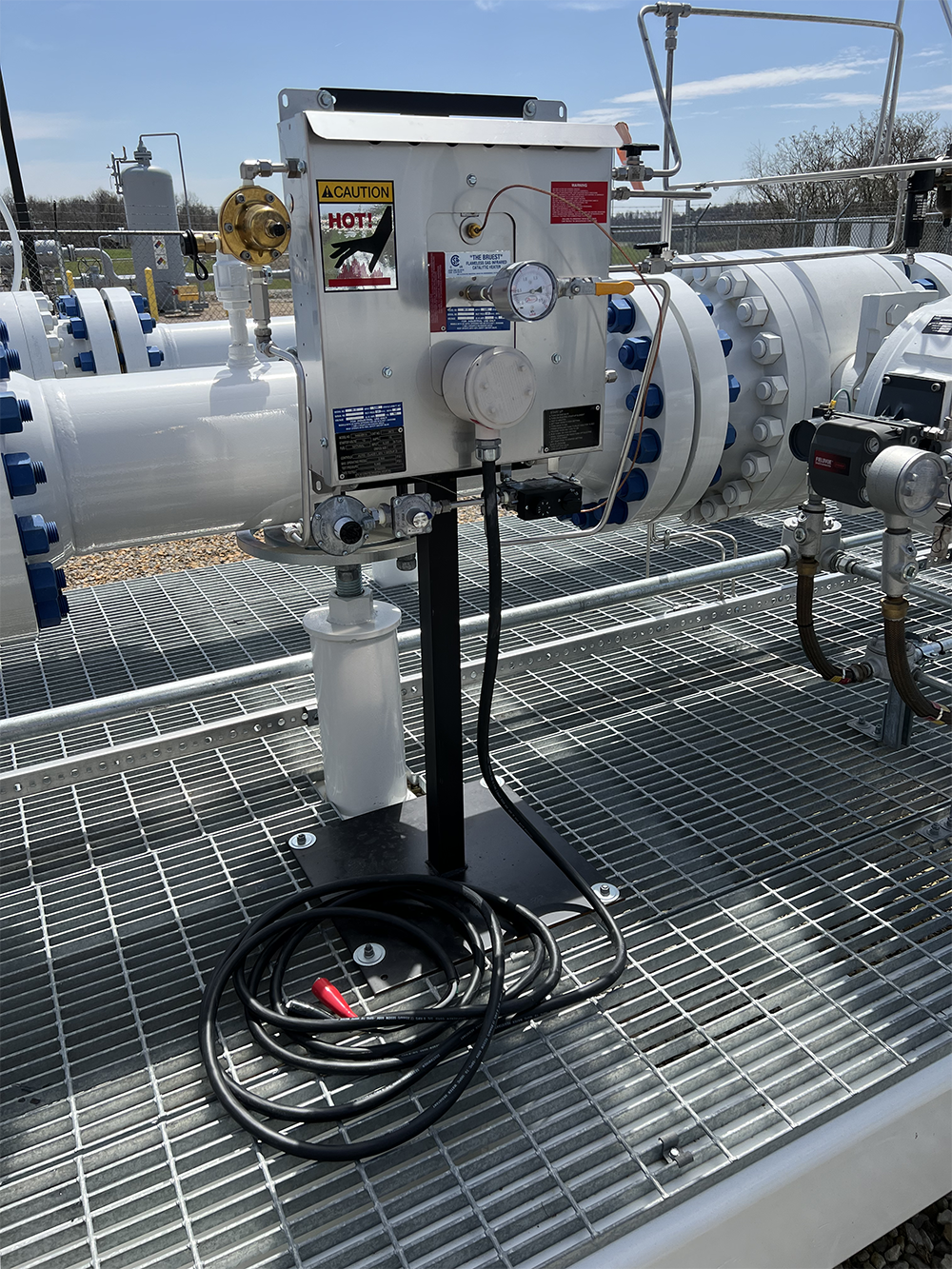

Freeze-FITER applied in front of an instrument preheats the gas

Thomas Kerr starting a Dual Coil Freez-FITER at a Compressor station

Bruest Catalytic Heaters are used wherever temperature control is critical, provide steady, flameless infrared heat to maintain proper operating temperatures in critical equipment.

Meter and regulator stations

Compressor buildings

Pipeline manifolds

Wellhead skids

Analyzer shelters and equipment enclosures

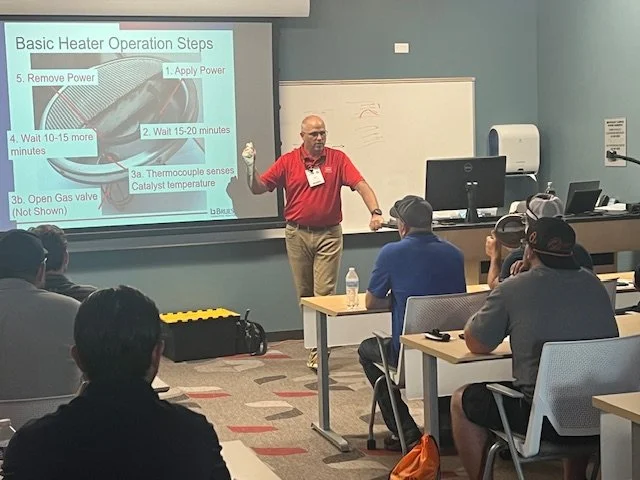

Catalytic Heater Fundamentals

Unlike conventional burners, catalytic heaters don’t rely on combustion. Instead, they use a catalytic reaction to release energy from natural gas or LPG at a much lower temperature—typically around 900°F (480°C) compared to the 1,200–1,400°F required for ignition. The result is safe, flameless infrared radiant heat—an exothermic chemical process that delivers steady warmth without sparks or smoke.

It’s not magic.. it’s an Exothermic chemical reaction.

DESIGNED FOR hazardous OR ENCLOSED ENVIRONMENTS

FREEZ-FITER with a Regulator

CSA Class I Div 1 or FM Class I Div 2

CSA and FM approvals for Class I, Division 1 and 2 locations

ATEX certification for European installations

Operates on natural gas or LPG

Catalytic Pads require little to no maintenance

No moving parts and minimal maintenance

Long service life with consistent, reliable output

HOTCAT LINE HEATERS

In HOTCAT natural gas line heaters, Bruest catalytic heater panels are the heat source. The catalytic heater panels convert the fuel gas to CO2, water vapor, and infrared heat with virtually no NOx. The process begins by preheating of the catalyst with electric power. Once the catalyst is preheated, fuel gas can be introduced to complete the startup. Manual or automated control systems are available for different application requirements.

David Kerr fine tuning a HOTCAT that heats fuel gas to power large, reciprocating compressors.

Cody Smith troubleshooting a HOTCAT at a regulator station in Virginia.

Daryl Smith diagnosed that the 11 yr old HOTCAT needed new heater pads.

resources

David Kerr teaching Bruest Heater Start Up and Operations

For Bruest Catalytic Heater support, training, maintenance or troubleshooting, connect with our Application Specialists.

MORE Applications for Catalytic Heaters

Since 1952, Kerr Engineered Sales Company has represented leading pipeline and performance equipment manufacturers across the Eastern U.S. Now in its fourth generation of family leadership, Kerr continues to serve the industry with the same commitment to quality, reliability, and personal service that has defined our company for more than 73 years.

TIPS TO CONSIDER WHEN PURCHASING CLOSURES

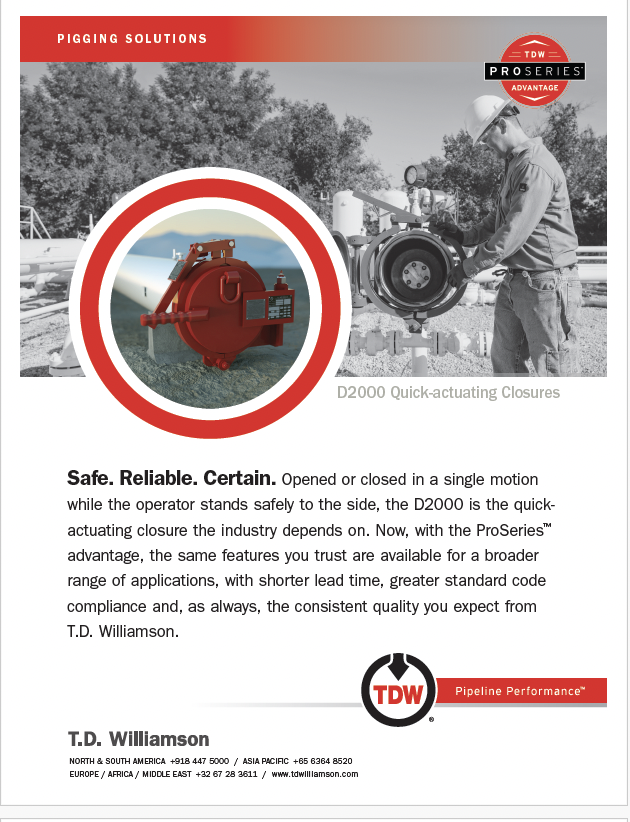

When selecting Closures, pipeline operators should consider safety and performance factors. The TDW D2000 Closures with the ProSeries™ Advantage is the safest, most trusted closure on the market.

“Imitation is the sincerest form of flattery that mediocrity can pay to greatness.”

Don’t compromise safety and performance by settling for imitations. When it comes to closures, cutting corners isn’t an option. The safety of your crews, the integrity of your pipeline, and the efficiency of your operation all hinge on choosing the right product.

TDW’s D2000 ProSeries closures are backed by more than 100 years of engineering expertise, field experience, and continuous innovation.

When you invest in the D2000 ProSeries, you’re not just buying a closure—you’re choosing the best-in-class solution backed by a manufacturer who will be here for the lifetime of your pipeline.

the manufacturer

Proven track record – Does the manufacturer have decades of field-proven reliability, or are they new to the market? TDW closures have been rigorously tested and trusted by operators worldwide for generations.

Life cycle support – A closure is only as good as its support. Look at availability of parts, repair services, and consumables like O-rings and Pressure Warning Locks (PWLs). TDW ensures long-term support for every component.

See the D2000 Closure in action

SAFETY FIRST

The primary question: Does the design keep the operator out of the danger zone?

Operator positioning – With the D2000, operators can safely open the closure from outside the direct line of danger.

Pressure Warning Locks – Placement matters. PWLs located in the 12 o’clock position are less likely to collect debris than those on the door face. The D2000 design directs any retained pressure safely away from the operator.

Durability and spares – Unlike metal-to-metal seals that wear out quickly, TDW’s PWLs are supported with readily available O-rings and replacement parts, ensuring reliability and uptime.

Design AND FEATURES that matter

Simplicity of operation – Fewer moving parts mean fewer failure points and easier maintenance.

Ease of alignment – A single pivot point makes aligning the door with the collar straightforward and efficient.

Clamping surface design – Closures with parallel, non-wedging clamp-rings eliminate force transfer to holding components, reducing wear compared to tapered, wedging surfaces.

O-Ring LOCATION and performance

Sealing performance is critical, and O-ring placement makes a big difference.

Protected placement – O-rings positioned on the external outer edge of the collar are less likely to be damaged during pig loading or removal, and they’re better protected from debris.

Leak prevention – Properly compressed O-rings perform even at low pressure, reducing leak risks.

Material options – TDW offers multiple O-ring materials to suit varying operating conditions, giving operators flexibility and reliability.

TDW closures are there for the lifetime of your pipeline.

At Kerr Engineered Sales Company, we know closures inside and out. For over 73 years, we’ve been helping operators make the right decisions for pipeline safety and efficiency. As TDW’s representative since 1952, we stand firmly behind their products and their commitment to excellence.

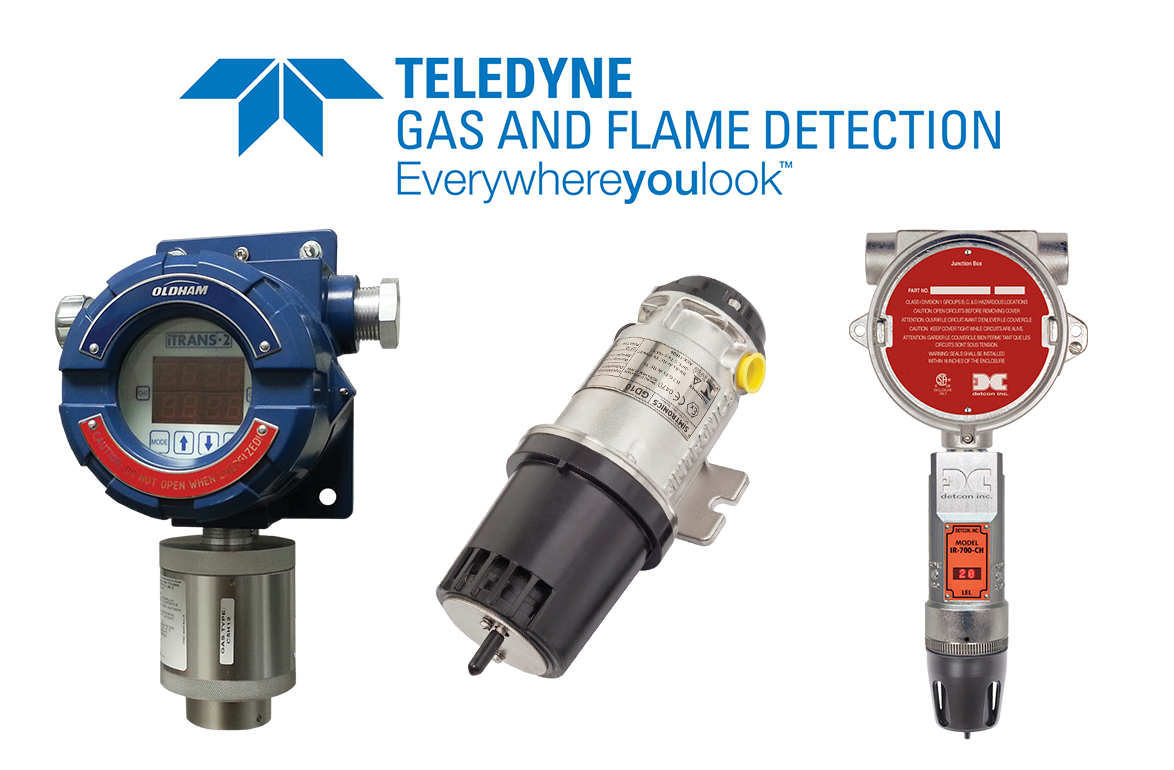

TELEDYNE FIXED GAS DETECTION SYSTEMS

Pittsburgh, PA - Kerr Engineered Sales Company announces new partnership with Teledyne, the leading provider of fixed gas detection systems.

FLAMMABLE AND TOXIC INDUSTRIAL GAS DETECTORS

September 2025 - Pittsburgh, PA

Kerr Engineered Sales Company announces new partnership with Teledyne. Unlike portable detectors, fixed detection devices make it possible to secure an entire area 24 hours a day. They can also be connected to a detection system, which displays the gas concentration in numerical value, and then triggers the servo-controls in the event of an abnormal value.

Detect abnormal or dangerous presence of gas in a specific area and warn users in the event of potential hazards. Some models are equipped with sensors that can measure the concentration of one or more types of gas.

TELEDYNE Products are stocked by United Products, KERR Engineered Sales distribution partner.

itrans 2

GD 10P

700 Series

““We are excited to partner with Teledyne fixed gas detectors. The best-in-class range of products meet the needs of pipeline operators for turnkey detection systems.”

Since 1952, Kerr Engineered Sales Company has been a trusted partner in the Eastern U.S., representing leading companies in pipeline repair and performance. A family-owned business for over seven decades, Kerr continues to deliver exceptional service and expertise dedicated to improving the life of pipelines.

Our Application Specialists at Kerr are available for team presentations, lunch and learns and site visits. We are here to help you optimize your gas utility operations and ensure the safety and efficiency of your equipment.