Operating Bruest Catalytic Heater

For 61 years, Kerr Engineered Sales has represented Bruest Catalytic Heaters, providing flameless, infrared catalytic heating solutions for the natural gas industry.Get an overview of catalytic heater operations, maintenance and troubleshooting tips.

For 61 years, Kerr Engineered Sales has represented Bruest Catalytic Heaters, providing flameless, infrared catalytic heating solutions for the natural gas industry.

This article has a general overview of catalytic heater operations, applications and troubleshooting tips.

The safest, most efficient alternative wherever flameless heat is required, Bruest Catalytic Heaters are found in heating applications along the gas network starting from the well head to the end user. Bruest leads the industry in engineering and manufacturing reliable, cost-efficient, green systems to prevent freeze-ups in critical metering and regulating equipment. Manufactured in Independence, Kansas, the catalytic heaters are used to heat meter buildings, platforms and pipelines.

KERR customers who have Bruest Catalytic Heaters count on our practical experience of how to start and operate the heaters. For operating new heaters, or ones that are decades old, our Application Specialists are on the ground to answer questions and provide support to ensure that the heaters are safe and working optimally.

Catalytic Heater Fundamentals

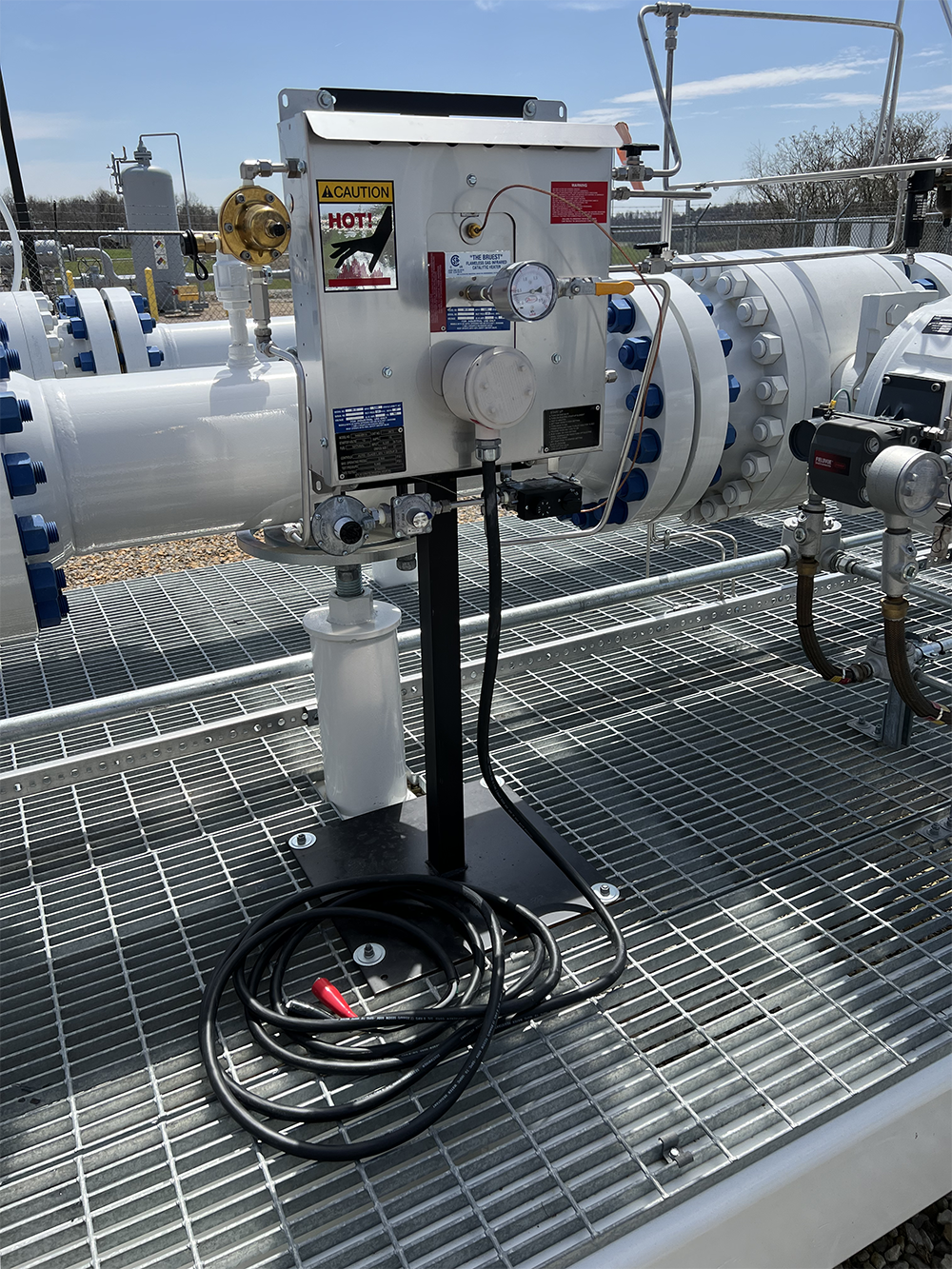

Bruest HOT CAT at a Town Border Station

Catalytic heaters produce flameless, infrared radiant heat. Bruest heaters cause natural gas to release its energy at a much lower temperature with a catalyst. The natural gas auto- ignition temperature is between 1200 - 1400 degrees Fahrenheit.

Bruest heaters operate at temperatures of around 900F-900F (426C to 483C.)

It’s not magic.. it’s an Exothermic chemical reaction.

bruest heaters are rated for hazardous locations

FREEZ-FITER with a Regulator

Bruest Catalytic Heaters are rated for operation by FM and CSA for operation in Class 1 Division 1 and 2 operation as well as ATEX for European applications. The catalytic heaters can be fueled with either Natural Gas or LPG.

CSA Class I Div 1 or FM Class I Div 2

Catalytic Pads require little to no maintenance

No moving parts

Thomas Kerr starting a Dual Coil Freez-FITER at a Compressor station

Freeze-FITER applied in front of an instrument preheats the gas

Cody Smith troubleshooting a HOTCAT at a regulator station in Virginia.

Daryl Smith diagnosed that the 11 yr old HOTCAT needed new heater pads.

BASIC BRUEST HEATER OPERATION START UP STEPS

Apply electric power – do not remove until the final step

Wait 15 minutes

(a) Thermocouple senses the catalytic temperature.

(b) Activate the safety valve to introduce fuel gasWait an additional 15 minutes

Remove the electric power

Maintenance and Trouble Shooting

There are no moving parts in a Bruest catalytic heater. Maintenance is minimal. The face of the heater (the catalyst) should be protected when cleaning in the area, as high pressure air or water can damage or destroy the catalyst.

When the heater is not in use, it should be stored where dirt and other materials will not collect on the catalyst surface. To prevent contamination or the possibility of insect or rodent damage to the catalyst during the summer or any long period out of service, heaters should be wrapped in plastic film or similar material.

Trouble Shooting CHECKS

HEATER POSITION - Check the gas supply. Is the pressure too high, or too low?

ELECTRIC START UP - Do you have the correct voltage? Are the cables too long? Are any of the cables cut?

PREHEATING - Did you preheat for 15-20 minutes as recommended? If it is the first time of the year running the heater, preheat a bit longer. An insufficiently preheated heater can shut off unexpectedly

THERMOCOUPLE CHECK - 10-15 mv. Do you have the correct Thermocouple?

VALVES - Check the Baso valve and check the Thermostatic Gas valve.

START UP COIL - Did you check the resistance on the start up coil?

FUEL GAS PRESSURE - Check that the Fuel gas pressure is sufficient. The heaters require 3.5” WC / 8.7mBar. A variance of +/- 0.5” wc / 1.2mBar are okay

TEMPERATURE CONTROLLERS - When using temperature controllers, make sure that the low fire bypass has sufficient fuel gas pressure. A Minimum of 1.5” WC / 4.4 mBar IS required.

SULFER CAUTION - If there is sulfur in the fuel gas, it can cause the heater to fail prematurely. The length of service will depend on the concentration and duration of operation. Bruest offers sulfur filters.

COMMON ISSUES & SOLUTIONS

CLEANING & PROTECTION

Bruest Heaters should be adequately protected from the weather and elements. Excessive moisture or wind can cause the heater to cease functioning. Check to see if the Pad is dirty.

Heaters should be cleaned only with soft, feather like devices to gently brush off any debris on the heater face.

Never use compressed air to clean the heaters.

For additional Bruest Catalytic Heater support, training, maintenance or troubleshooting, contact us to speak with KERR’s Application Specialists.

Bruest Catalytic Heater Installation & Operation Guide

Kerr Engineered Sales Company has been representing leading pipeline repair and performance companies in Eastern US since the company was founded in 1952. Seventy two years later, the company is a third generation family run business serving customers with the highest quality service and support.

HJ3 CARBONSEAL™ PIPELINE REPAIR

NEW REPRESENTATION: November, 2024 - Pittsburgh, PA Kerr Engineered Sales Company announces new representation of HJ3’s line of Pipeline Repair Systems, designed to address corrosion, erosion, dents, weld defects and metal loss common with pipeline operation.

HJ3's CarbonSeal™ pipe repair system

November, 2024 - Pittsburgh, PA Kerr Engineered Sales Company announces new partnership with HJ3, the global leader in composite systems to repair tanks, pipe, silos and concrete structures. HJ3 is a manufacturer of composite repair systems (composite wraps) that are proven to strengthen corroded or damaged pipelines. The company is based in Tucson, AZ.

Kerr will be representing HJ3’s line of Pipeline Repair Systems, designed to address corrosion, erosion, dents, weld defects and metal loss common with pipeline operation. The engineered repair systems are qualified for repairing defects in high pressure pipelines, with superior strength and durability compared to competing products.

CarbonSeal™ passed rigorous testing as a superior pipe repair solution.

HJ3's CarbonSeal™ pipe repair system is a pioneering solution that excels in addressing a broad spectrum of common applications. CarbonSeal™ is a high strength carbon fiber composite system designed in compliance with ASME PCC-2 Article 4.1, ASME B31 standards and ISO 24817. CarbonSeal™ can be applied to process piping systems and pipelines to restore integrity lost due to corrosion. CarbonSeal™ repairs are fully supported with structural calculations performed by licensed professional engineers who specialize in composite design.

“We are thrilled to be represented by Kerr Engineered Sales. The team has been highly regarded in the natural gas industry for decades. KERR consistently demonstrates a deep understanding of their customers pipeline repair and maintenance needs. ”

Kerr Engineered Sales Company has been representing leading pipeline repair and performance companies in the Eastern US since the company was founded in 1952. Seventy-two years later, the company remains a family business delivering the highest quality service and expertise.

Our Application Specialists at Kerr are available for team presentations, lunch and learns and site visits. We are here to help you optimize your gas utility operations and ensure the safety and efficiency of your equipment.

GAS ANALYSIS & ODORIZATION TURNKEY SYSTEMS

November, 2024 - Pittsburgh, PA Kerr Engineered Sales Company announces new partnership with Consolidated Analytical Systems (CAS), the industry leader in the design, manufacture and integration of Natural Gas and Ambient Air Monitoring Shelters and Enclosures.

Trailer Mounted Turnkey System

November, 2024 - Pittsburgh, PA

Kerr Engineered Sales Company announces new partnership with Consolidated Analytical Systems (CAS), the industry leader in the design, manufacture and integration of natural gas analysis and odorization systems.

Based in Cincinnati, OH, Consolidated Analytical Systems (CAS) specializes in creating custom monitoring solutions for natural gas pipelines, including turnkey systems tailored to meet customer-specific requirements such as size, analytical needs, and hazardous area classifications. CAS provides a full range of advanced industrial and field-deployable gas chromatographs for VOCs, speciated sulfurs, impurity measurement, mercaptan identification, and odorization.

Mini Shelter with Rack Mounted MEDOR

CAS turnkey, fixed and mobile solutions are built specifically to the customer’s needs including size, analytical requirements and hazardous area classification. A complete line of industrial and field-deployable gas chromatographs for VOCs and speciated sulfurs is available as well as Natural Gas impurity measurement, mercaptan identification and odorization.

The systems can be housed in containerized, trailer and infrastructure enclosures.

CAS shelters provide flexibility when site-specific requirements are driving a project.

Customer required equipment can be integrated into custom built structures.

Infrastructure Turnkey System

Containerized Turnkey System

““We are proud to be represented by Kerr Engineered Sales. Kerr’s reputation for understanding customer needs and their focus on safety, performance, and efficiency aligns perfectly with our mission.””

Since 1952, Kerr Engineered Sales Company has been a trusted partner in the Eastern U.S., representing leading companies in pipeline repair and performance. A family-owned business for over seven decades, Kerr continues to deliver exceptional service and expertise.

Our Application Specialists at Kerr are available for team presentations, lunch and learns and site visits. We are here to help you optimize your gas utility operations and ensure the safety and efficiency of your equipment.

CLOSING TDW D2000 CLOSURES

The D2000 quick-actuating closure combines operator safety with ease of operation. After depressurization, closing operations are performed in a fast, single motion. Here’s a quick guide to closing procedures.

TDW PIGGING INSIGHTS - Episode 6

A quick guide to closing and maintaining the D2000 Closure.

D2000 Quick-Actuating Closure

The D2000 quick-actuating closure combines operator safety with ease of operation. After depressurization, opening and closing operations are performed in a fast, single motion, with the operator standing safely to the side. The D2000 closure maximizes efficiency and reduces both, personal operator risk and company operational cost.

CLOSING PROCEDURES

Before closing, inspect, clean, and lubricate the O-Ring on the barrel collar, including the O Ring grooves and sealing surfaces

Push the door firmly shut with no gap between the door face and hub face.

Pull down on the clamp ring handle to close the door.

Install the pressure warning lock screw, make sure it is not cross threaded.

Hand tighten the pressure warning lock screw and then add about one eighth of a turn with a wrench. Do not over tighten.

MAINTENANCE TIPS TO BE DONE REGULARLY

Lubricate all the pivot point on top of the clamp ring assembly, front and back, as well as door hinge, top and bottom

Keep all the exterior surfaces painted to prevent rust

Other blogs you may be interested in:

If you have questions, please contact the Kerr Engineered Sales Company who are also available for team presentations, lunch and learns and customer visits.