SCHEDULE A TDW DEMONSTRATION

From Vermont to Virginia, the team at Kerr is on the road working with gas utilities and companies to ensure safe and efficient pipeline repair and maintenance. Gas utilities are investing in equipment such as the TDW POLYSTOPP® Quick Connect system.

From Vermont to Virginia, the team at Kerr is constantly on the road working with gas utilities and companies to ensure safe and efficient pipeline repair and maintenance.

Increasingly, gas utilities are investing in equipment such as the TDW POLYSTOPP® Quick Connect system. The POLYSTOPP® Quick Connect system makes it easy to safely perform hot tapping, plugging and branching on polyethylene (PE) pipelines. The lightweight design allows operators to isolate a polyethylene (PE) line twice as fast as other methods while preventing the damage associated with squeezing.

Recent product demonstrations have highlighted how to operate the equipment properly.

Daryl Smith, Cody Smith demonstrating TDW POLYSTOPP® Quick Connect to a New York City gas utility

For 72 years, Kerr has been supporting customers with all of their service and equipment needs. Our hands-on approach ensures that customers are fully equipped to operate their equipment safely and efficiently. We visit project sites and facilities, providing sessions that are tailored specifically for the equipment and applications the customer utilizes.

Components of a Demonstration

Equipment Setup and Installation: Step-by-step guidance on the proper installation of the POLYSTOPP® Quick Connect system.

Operational Best Practices: Detailed instructions on how to operate the equipment safely and effectively.

Maintenance Procedures: Tips and protocols for maintaining the equipment to ensure longevity and optimal performance.

Safety Protocols: Comprehensive safety guidelines to protect operators and bystanders.

Troubleshooting: Solutions to common issues that may arise during operation.

Ron Comer and Daryl Smith with the TDW POLYSTOPP® PE QUICK CONNECT at a New Jersey gas utility

A successful TDW POLYSTOPP® PE QUICK CONNECT demo at a gas utility in West Virginia

Daryl Smith assisting a customer

To schedule a training or a demonstration for your company, just reach out. We are here to help you optimize your gas utility operations and ensure the safety and efficiency of your equipment.

Kerr Engineered Sales Company has been representing leading pipeline repair and performance companies in Eastern US since the company was founded in 1952. Seventy two years later, the company remains a family business serving customers with the highest quality service and expertise.

Our application specialists at Kerr Engineered Sales Company are also available for demonstrations, team presentations, lunch and learns and customer visits.

OPENING TDW D2000 CLOSURES

The D2000 quick-actuating closure combines operator safety with ease of operation. After depressurization, opening and closing operations are performed in a fast, single motion. Here’s a quick guide to opening the closure.

TDW PIGGING INSIGHTS - Episode 5

A quick guide to opening and maintaining the D2000 Closure.

D2000 Quick-Actuating Closure

The D2000 quick-actuating closure combines operator safety with ease of operation. After depressurization, opening and closing operations are performed in a fast, single motion, with the operator standing safely to the side. The D2000 closure maximizes efficiency and reduces both, personal operator risk and company operational cost.

OPENING

To safely open the TDW D2000 clamp ring closure door, follow these procedures:

Isolate the vessel from line pressure, bleed the pressure to 0 psig and drain.

Always stand on the side of the closure that is opposite the door hinge.

Open the pressure warning lock by turning the screw counterclockwise. If there is still gas in the line, tighten pressure warning lock and continue to bleed pressure until 0 psig, then continue procedure again.

Inspect the pressure warning lock, O-Ring and the bushing.

Lift the clamp ring handle and put the pressure warning lock in the hole furthest to the right.

Clean and lubricate the interior surface of the clamp ring.

MAINTENANCE TIPS TO BE DONE REGULARLY

Lubricate all the pivot point on top of the clamp ring assembly, front and back, as well as door hinge, top and bottom

Keep all the exterior surfaces painted to prevent rust

Check out our Pig Resource page.

If you have questions, please contact the Kerr Engineered Sales Company who are also available for team presentations, lunch and learns and customer visits.

TIE-IN SOLUTION FOR PIGGING-COMPATIBLE GAS PIPELINES

An elegant tie-in solution was necessary for maintaining the piggability of main pipelines. Two 12-inch natural gas lines needed to be connected to a new well site near Pittsburgh. An innovative solution was used with TDW fittings and pig guide bars.

When maintaining the piggability of main lines was crucial, an elegant tie-in solution WAS necessary.

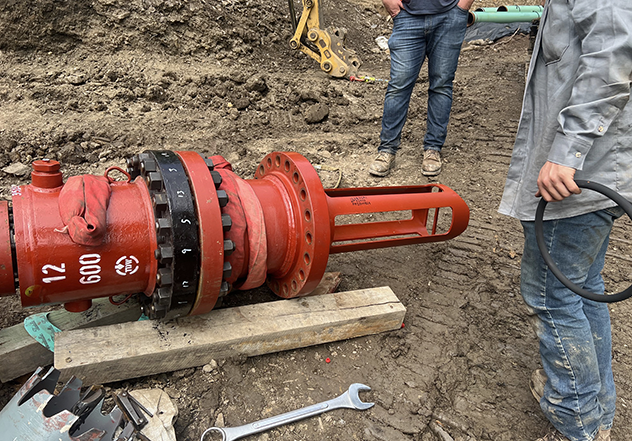

The job site with the two 12-inch x 12-inch 3-WAY™ Tee Fittings

Project Overview

A new natural gas well was being completed near Pittsburgh, necessitating the connection of two 12-inch lines from the well site to two 12-inch main lines. The 12-inch main lines needed to remain piggable.

Design & IMPLEMENTATION

To meet these requirements, an innovative solution using TDW 12-inch x 12-inch 600 class 3-WAY™ Tee Fittings with LOCK-O-RING® and pig guide bars was used. The LOCK-O-RING® completion plug features an interlock system that helps eliminate potential leak paths and ensures proper seating. The implementation process included:

Fitting Installation: The 3-WAY™ Tee Fittings were welded onto the 12-inch main lines.

Pipeline Connection: The 12-inch pipes with valves were welded to the 12-inch outlets on the fittings.

Hot Tapping: TDW service technicians performed two 12-inch Hot Taps.

Completion Plug Setting: The completion plugs with pig guide bars were set into the fittings by the TDW service technicians.

One of the completion plugs with pig guide bars

This approach allowed for the seamless integration of the new well site while maintaining the piggability of the main lines. By utilizing TDW's advanced fitting and plug technology, the tie-in solution not only met the immediate operational needs but also provided long-term reliability and safety for the pipeline system.

Kerr Engineered Sales Company has been representing leading pipeline repair and performance companies in Eastern US since the company was founded in 1952. Seventy two years later, the company remains a family business serving customers with the highest quality service and expertise.

Our application specialists at Kerr Engineered Sales Company are also available for demonstrations, team presentations, lunch and learns and customer visits.

PREVENTING REGULATORS FROM FREEZING

A compressor station in Eastern PA installed a Bruest Freez-Fiter S20000 to prevent the regulators from freezing prior to cutting the pressure from 1083 psi to 200 psi. If the regulators freeze, they will not work as designed to cut down the pressure.

A compressor station in Eastern PA installed a Bruest Freez-Fiter S20000 to prevent the regulators from freezing prior to cutting the pressure from 1083 psi to 200 psi. If the regulators freeze, they will not work as designed to cut down the pressure. Bruest Freez-Fiters were designed to heat low to medium volume of gas with one or more catalytic heater panels to heat a serpentine process gas coil.

For 60 years, Bruest Catalytic Heater has provided flameless, infrared catalytic heating solutions for the natural gas industry.

The green valve connects to the Freez-Fiter control panel that starts and monitors the heater.

The gray enclosure on the right contains the Freez-Fiter control panel that starts and monitors the Freez-Fiter. The green valve was opened so that the natural gas could flow through the Freez-Fiter and the regulators.

HOW BRUEST HEATERS WORK

Freez-Fiter pilot gas heaters safely and effectively heat low volumes of gas used by pilot regulators and instruments. An electric source is required to warm up the catalytic pad. Once the pads are warmed up, which should take between 15 to 20 minutes, the electric supply can be removed and the gas supply takes over. After the gas is introduced, the catalytic reaction will supply the necessary heat to continue the process. The gas travels through the heat exchange coil to be heated by the infrared heat.

Bruest’s Catalytic Heaters are flameless, free of emissions, low maintenance and safe for hazardous locations. Made in Independence, Kansas, Bruest Catalytic Heaters are the safest, most efficient alternative wherever flameless heat is required.

For additional Bruest Catalytic Heater support, training, maintenance or troubleshooting, contact us to speak with KERR’s Application Specialists.

Kerr Engineered Sales Company has been representing leading pipeline repair and performance companies in Eastern US since the company was founded in 1952. Seventy two years later, the company is a third generation family run business serving customers with the highest quality service and support.